ABSTRACT

The researcher decided to conduct this study to find other sources of fiber in making paper.

The reSearcher gathered all the materials to be needed. The sodium hydroxide was disolved into water. The cogon grass was added and it was heated. Now, the pulp was rinsed and bleached. On a clean basin with water, the pulp was transferred. A mold was dipped into it. The mold was left to dry.

The researcher therefor conclude that we can produce paper out of cogon grass.

The researcher would like to thank the following:

Mrs. Balve Granido, eventhough it is a general knowledge that it is your job to teach and guide us in making research papers, a heartfelt and sincere thanks to you Ma'am;

my parents, for their financial support;

and to God,for making this project a success.

A. Background of the Study

Cogon grass, Imperata cylindrica (L.) Beauv., has been ranked as one of the ten worst weeds of the world (Holm et al., 1977) (Fig. 1). In tropical and subtropical regions around the globe, this aggressive, rhizomatous perennial is generally considered a pernicious pest plant due to its ability to successfully disperse, colonize, spread, and subsequently compete with and displace desirable vegetation and disrupt ecosystems over a wide range of environmental conditions (Holm et al., 1977; Brook, 1989; Bryson and Carter, 1993; Dozier et al., 1998). These characteristics and consequences of cogon grass infestations are similarly evident even within the native or endemic range in the Eastern Hemisphere, as it has long been considered one of Southeast Asia’s most noxious weeds (Brook, 1989).And because of this reason, the researcher decided to conduct a study making cogon grass as the main component of it. Since cogon grass is fibrous, the researcher then decided to make paper out of it.

B. Statement of the Problem

Is there any possibility of producing paper out of Cogon grass?

C. Hypothesis

There is a possibility of producing paper out of Cogon grass.

D. Significance of the Study

It is stated earlier that Cogon grass is considered as a weed. If this study becomes successful, then it will be a good news to all the people because they can make money out of this weed. And another reason is that there would now be many sources of paper for paper making.

E. Scope and Limitation

This study is only limited in knowing or finding out if there is any possibility that we can produce paper out of cogon grass.

F. Definition of Terms

- paper - is thin material mainly used for writing upon, printing upon or packaging. It is produced by the amalgamation of fibers, typically vegetable fibers composed of cellulose, which are subsequently held together by hydrogen bonding.

- Cogon grass - is a species of grass in the genus Impera. It i s placedin the subfamily Panicoideae, supertribe Andropogonodae, tribe Andropogoneae. It is a perinneal rhizomatous grass native to east and southeast Asia, India, Micronesia and Australia. It grows from 0.6-3 m (2-10 feet) tall. The leavesare about 2 cm wide near the base of the plant and narrow to a sharp point at the top; the margins are finely toothed and are embedded with sharp silica crystals. The main vein is a lighter colour than the rest of the leaf and tends to be nearer to one side of the leaf. The upper surface is hairy near the base of the plant while the underside is usually hairless. Roots are up to 1.2 meters deep, but 0.4 m is typical in sandy soil.

CHAPTER 2

Review of Related Literature

Paper is a very important thing nowadays. We write or print documents on paper. Paper can be produced with a wide variety of properties, depending on its intended use. We use paper to represent values like paper money, bank note, cheque, voucher and ticket. For entertainment, we make books, magazines and newspaper from paper.

Almost all of the paper you use today is made of wood fibers. Some specialty papers, like stationery and money, are made from linen, cotton, or other plants. Other papers contain a combination of cellulose fibers and synthetics such as latex. Still others are made completely from synthetic materials such as polyolefine. You might find latex in a waterproof mariner's chart, or polyolefine in a rugged courier envelope. But you'll find natural fiber paper almost everywhere! Because of it's high demand in the market, many experiments have been made to find new sources of making paper.

- cogon grass

- sodium hydroxide

- mold

- deckle

- cloth

- pot

- stirring rod

The researcher first gathered all the materials needed. 50 grams of sodium hydroxide was disolved in 100 mL water . 50 leaves of cogon grass was added to the solution. The solution was heated for 10 min. It was then left for 30 min. The pulp was strained from the solution and was rinsed thoroughly. The pulp was then bleached over and over until the desired color was attained. It was then rinsed and strained again. On a basin, a clean water was prepared and the pulp was added. The mold was dipped in the basin and was haken back and forth and side to side. Then the mold was left for 30 min and was left to dry.

CHAPTER 4

Results and Discussion

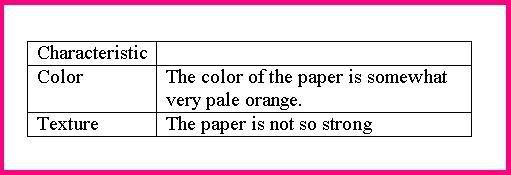

Many ratios of the mixture was tested to achieve the right mixture. The thickness of the paper depends on the amount of the pulp and water. If you want a thicker paper, you must increase the amount of the pulp. If you want a thinner paper, you must increase the amount of water.

Conclusion and Recomendation

With the data above, the researcher therefor conclude that we can produce paper out of cogon grass.

This study needs a lot of improve ment especially on how to make the product more stronger. The bleaching process should also be improved.